Steel industry

Products

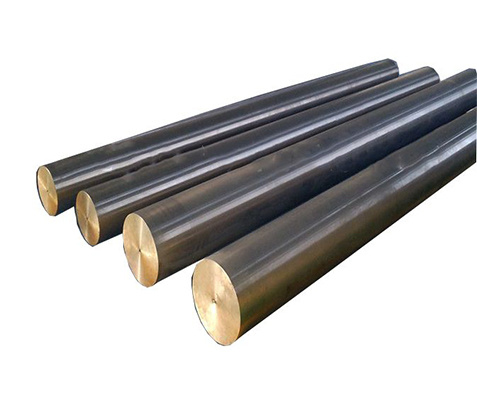

GCr15 hot rolled steel round bars

i

According to different materials and application industries,

the production capacity and particle size range will vary.

Please contact our engineers to customize the equipment for you. Our experts will contact you within 6 hours to discuss your machine and process needs.

Keywords:

Enquiry

sun@sdbaixinxinsteel.com

Product introduction

GCr15 is a common steel which is used to produce balls and rings of bearing. The product has characteristics of the uniform-chemical composition, low percentage of harmful elements, high purity, well-distributed carbide, good surface quality. It also has characteristics of a wide scope of plastic,stable heat-treatment quality, uniform, and high hardness, high wear resistance,high strength of touching fatigue. It has excellent machining property after spheroidize annealing. GB GCr15 bearing steel is GB standard Alloy Bearing steel, It belong to the high-quality high carbon, alloy chromium, manganese steel. GB GCr15 properties is a chromium, manganese alloy steel specification. GCr15 is equivalent to AISI 52100, DIN 100Cr6. Most applications can replace each other.

Technical data

Chemical composition

| C(%) | 0.95~1.05 | Si(%) | 0.15~0.35 | Mn(%) | 0.25~0.45 | P(%) | ≤0.025 |

| S(%) | ≤0.025 | Cr(%) | 1.40~1.65 |

Mechanical Properties

The mechanical properties of annealed GB GCr15 bearing steel (typical for steel) are outlined in the table below:

| Tensile | Yield | Bulk modulus | Shear modulus | Poisson’s ratio | Thermal conductivity |

| MPa | Mpa | Gpa | Gpa | W/mK | |

| 520 | 415 Min | 140 | 80 | 0.27-0.30 | 46.6 |

Heat treatment Related

- Annealing of GCr15 Alloy bearing steel

Slowly heated to 790-810 ℃ and allow enough times, let the steel to be thoroughly heated, Then cool slowly in the furnace. Different annealing ways will get different hardness.The GCr15 bearing steel will get Hardness MAX 248 HB (Brinell hardness).

- Quenching and temperature of GCr15 Alloy bearing steel

Heated slowly to 860°C, Then quenching by oil get 62 to 66 HRc hardness. High temperature tempering: 650-700℃,cool in air, get hardness 22 to 30HRC. Low temperature tempering: 150-170 ℃, Cool in ari, get 61-66HRC hardness.

- Hot work and cold work of GCr15 Alloy bearing steel

GB GCr15 steel can hot worked at 205 to 538°C, GCr15 Bearing steel can be cold worked using conventional techniques in the annealed or normalized conditions.

Applications

GB GCr15 steel is widely used for a variety of applications in the used to the bearings in rotating machinery. Typical applications such as valve bodies, pumps and fittings, the high load of wheel, bolts, double-headed bolts, gears, internal combustion engine. Electric locomotives, machine tools, tractors, steel rolling equipment, boring machine, railway vehicle, and mining machinery transmission shaft on the steel ball, roller and shaft sleeve, etc.

Application industry

Company's products: stainless steel series, carbon steel series, aluminum series, copper series, galvanized, color coated, coiled materials, seamless pipes, welded pipes, square pipes, torsion pipes, round bars, angle steels, channel steels, I-beams , Hexagonal steel, square steel, flat steel, steel wire, welding rod, flange cutting parts and other stainless steel and high nickel alloy steel. For customers to buy. The products sell well all over the country and are exported to more than 50 countries including the European Union, the United States, Australia, Southeast Asia, and the Middle East. They are widely used in the Three Gorges Project, Capital International Airport, Shanghai Pudong International Airport, the 2008 Olympic Games venues, and China (Hong Kong) Gas International Co., Ltd. natural gas transformation Project, Jinjin Expressway and many other national key projects.

Company's products: stainless steel series, carbon steel series, aluminum series, copper series, galvanized, color coated, coiled materials, seamless pipes, welded pipes, square pipes, torsion pipes, round bars, angle steels, channel steels, I-beams , Hexagonal steel, square steel, flat steel, steel wire, welding rod, flange cutting parts and other stainless steel and high nickel alloy steel. For customers to buy. The products sell well all over the country and are exported to more than 50 countries including the European Union, the United States, Australia, Southeast Asia, and the Middle East. They are widely used in the Three Gorges Project, Capital International Airport, Shanghai Pudong International Airport, the 2008 Olympic Games venues, and China (Hong Kong) Gas International Co., Ltd. natural gas transformation Project, Jinjin Expressway and many other national key projects.

Company's products: stainless steel series, carbon steel series, aluminum series, copper series, galvanized, color coated, coiled materials, seamless pipes, welded pipes, square pipes, torsion pipes, round bars, angle steels, channel steels, I-beams , Hexagonal steel, square steel, flat steel, steel wire, welding rod, flange cutting parts and other stainless steel and high nickel alloy steel. For customers to buy. The products sell well all over the country and are exported to more than 50 countries including the European Union, the United States, Australia, Southeast Asia, and the Middle East. They are widely used in the Three Gorges Project, Capital International Airport, Shanghai Pudong International Airport, the 2008 Olympic Games venues, and China (Hong Kong) Gas International Co., Ltd. natural gas transformation Project, Jinjin Expressway and many other national key projects.

Company's products: stainless steel series, carbon steel series, aluminum series, copper series, galvanized, color coated, coiled materials, seamless pipes, welded pipes, square pipes, torsion pipes, round bars, angle steels, channel steels, I-beams , Hexagonal steel, square steel, flat steel, steel wire, welding rod, flange cutting parts and other stainless steel and high nickel alloy steel. For customers to buy. The products sell well all over the country and are exported to more than 50 countries including the European Union, the United States, Australia, Southeast Asia, and the Middle East. They are widely used in the Three Gorges Project, Capital International Airport, Shanghai Pudong International Airport, the 2008 Olympic Games venues, and China (Hong Kong) Gas International Co., Ltd. natural gas transformation Project, Jinjin Expressway and many other national key projects.

Company's products: stainless steel series, carbon steel series, aluminum series, copper series, galvanized, color coated, coiled materials, seamless pipes, welded pipes, square pipes, torsion pipes, round bars, angle steels, channel steels, I-beams , Hexagonal steel, square steel, flat steel, steel wire, welding rod, flange cutting parts and other stainless steel and high nickel alloy steel. For customers to buy. The products sell well all over the country and are exported to more than 50 countries including the European Union, the United States, Australia, Southeast Asia, and the Middle East. They are widely used in the Three Gorges Project, Capital International Airport, Shanghai Pudong International Airport, the 2008 Olympic Games venues, and China (Hong Kong) Gas International Co., Ltd. natural gas transformation Project, Jinjin Expressway and many other national key projects.

Company's products: stainless steel series, carbon steel series, aluminum series, copper series, galvanized, color coated, coiled materials, seamless pipes, welded pipes, square pipes, torsion pipes, round bars, angle steels, channel steels, I-beams , Hexagonal steel, square steel, flat steel, steel wire, welding rod, flange cutting parts and other stainless steel and high nickel alloy steel. For customers to buy. The products sell well all over the country and are exported to more than 50 countries including the European Union, the United States, Australia, Southeast Asia, and the Middle East. They are widely used in the Three Gorges Project, Capital International Airport, Shanghai Pudong International Airport, the 2008 Olympic Games venues, and China (Hong Kong) Gas International Co., Ltd. natural gas transformation Project, Jinjin Expressway and many other national key projects.

Specification

-

- Commodity name: GCr15 hot rolled steel round bars

<strong>GCr15</strong> is a common steel which is used to produce balls and rings of bearing.GB GCr15 bearing steel is GB standard Alloy Bearing steel, It belong to the high quality high carbon, alloy chromium,manganese steel.

Product introduction

GCr15 is a common steel which is used to produce balls and rings of bearing. The product has characteristics of the uniform-chemical composition, low percentage of harmful elements, high purity, well-distributed carbide, good surface quality. It also has characteristics of a wide scope of plastic,stable heat-treatment quality, uniform, and high hardness, high wear resistance,high strength of touching fatigue. It has excellent machining property after spheroidize annealing. GB GCr15 bearing steel is GB standard Alloy Bearing steel, It belong to the high-quality high carbon, alloy chromium, manganese steel. GB GCr15 properties is a chromium, manganese alloy steel specification. GCr15 is equivalent to AISI 52100, DIN 100Cr6. Most applications can replace each other.

Technical data

Chemical composition

C(%) 0.95~1.05 Si(%) 0.15~0.35 Mn(%) 0.25~0.45 P(%) ≤0.025 S(%) ≤0.025 Cr(%) 1.40~1.65 Mechanical Properties

The mechanical properties of annealed GB GCr15 bearing steel (typical for steel) are outlined in the table below:

Tensile Yield Bulk modulus Shear modulus Poisson’s ratio Thermal conductivity MPa Mpa Gpa Gpa W/mK 520 415 Min 140 80 0.27-0.30 46.6 Heat treatment Related

- Annealing of GCr15 Alloy bearing steel

Slowly heated to 790-810 ℃ and allow enough times, let the steel to be thoroughly heated, Then cool slowly in the furnace. Different annealing ways will get different hardness.The GCr15 bearing steel will get Hardness MAX 248 HB (Brinell hardness).

- Quenching and temperature of GCr15 Alloy bearing steel

Heated slowly to 860°C, Then quenching by oil get 62 to 66 HRc hardness. High temperature tempering: 650-700℃,cool in air, get hardness 22 to 30HRC. Low temperature tempering: 150-170 ℃, Cool in ari, get 61-66HRC hardness.

- Hot work and cold work of GCr15 Alloy bearing steel

GB GCr15 steel can hot worked at 205 to 538°C, GCr15 Bearing steel can be cold worked using conventional techniques in the annealed or normalized conditions.

Applications

GB GCr15 steel is widely used for a variety of applications in the used to the bearings in rotating machinery. Typical applications such as valve bodies, pumps and fittings, the high load of wheel, bolts, double-headed bolts, gears, internal combustion engine. Electric locomotives, machine tools, tractors, steel rolling equipment, boring machine, railway vehicle, and mining machinery transmission shaft on the steel ball, roller and shaft sleeve, etc.

Relevant Items

CCS AH40 DH40 EH40 FH40 Marine Steel Plate

Higher-strength CCS shipbuilding steel comes in 12 grades of 3

strengths, AH40 is one of the grades. The CCS AH40 grade steel

plates have yield strength of 56,500 psi (390 MPa), and ultimate

tensile strength of 74,000 - 94,500 psi (510-650 MPa).

GCr15 hot rolled steel round bars

Cold rolled steel is our most common and commonly used cold rolled products.Its brand can be generally divided into: SPCC, SPCD, SPCE.

Relevant Items

Please fill out the form below,

Our experts will contact you within 6 hours to discuss your machine and process needs.